Undergraduate Capstone: Comprehensive Case Analysis: Tesla Disrupting the Automotive Industry

Capstone Comprehensive Case Analysis:

Tesla: Disrupting the Automotive Industry

Samuel A. Cypert II

The University of Central Oklahoma

College of Business

Author Note

This report was created in conjunction with Strategic Management under Dr. Lalit Manral while completing undergraduate coursework at the University of Central Oklahoma. This report counts as the final semester project for the capstone to the Legal Studies major offered at the University of Central Oklahoma in Edmond, Oklahoma.

Introduction

Over the past few decades, Elon Musk has evolved himself from becoming an industrial pioneer to household celebrity known by every American in the United States. The country has witnessed the introduction and wild success of PayPal within the e-commerce financial industry, Tesla within the automotive industry, SpaceX within the space exploration industry, SolarCity within the solar energy industry, The Boring Company within the infrastructure development industry, and Neuralink within the artificial intelligence industry. While all these companies have grown to be significant players in each of their respective industries, it was Tesla that first earned Musk his stardom in both the United States and abroad.

With the initial introduction of the Tesla Roadster, quickly followed by the Model S, what was once a little-known company based in Silicon Valley in California quickly became a national brand with sought-after vehicles that were new, technologically-savvy, and much more efficient in energy consumption compared to internal combustion engine automobiles. Consumer reviewing organizations such as Consumer Reports and Motor Trend gave the vehicles the highest accolades that could possibly be awarded by their scoring metrics, and envy grew among the middle class as the vehicles continued to increase in circulation.

With this being said, although Tesla has seen tremendous success in the United States and is quickly growing in popularity around the rest of the world, there are some internal issues that both Elon Musk and the company must work to fix in order to ensure its continued success around the world. Contained within this report are a summary of the issues Tesla is facing, analyses of company performance, alternatives to assist with improving these issues within the organization, a final strategic recommendation, and conclusion.

Problem Summary

Tesla is a corporation that has achieved a lot of growth and progress within a very short period of time compared to the established automotive companies in the United States that are known today. In 2003, Elon Musk officially created the company under the title of “Tesla Motors, Inc,” named after electricity pioneer Nikola Tesla, in the state of California. Two years later, investors and speculators deemed the company to be valuable enough that Musk was able to list Tesla in the NASDAQ stock exchange for an initial public offering so additional money could be gained from external public investors (Grant, 2018).

With all of this short-term success, however, one of the largest issues that Tesla began facing during the early stages of the 2010s was keeping up with forecasts for production and cash flow. As reported by Robert Grant, Tesla faced public embarrassment after (1) they missed their target of producing five thousand new Model 3’s per week in the U.S. by six months and (2) news to investors that Tesla had also missed their target of achieving positive free cash flow by the second half of 2018 (Grant, 2018).

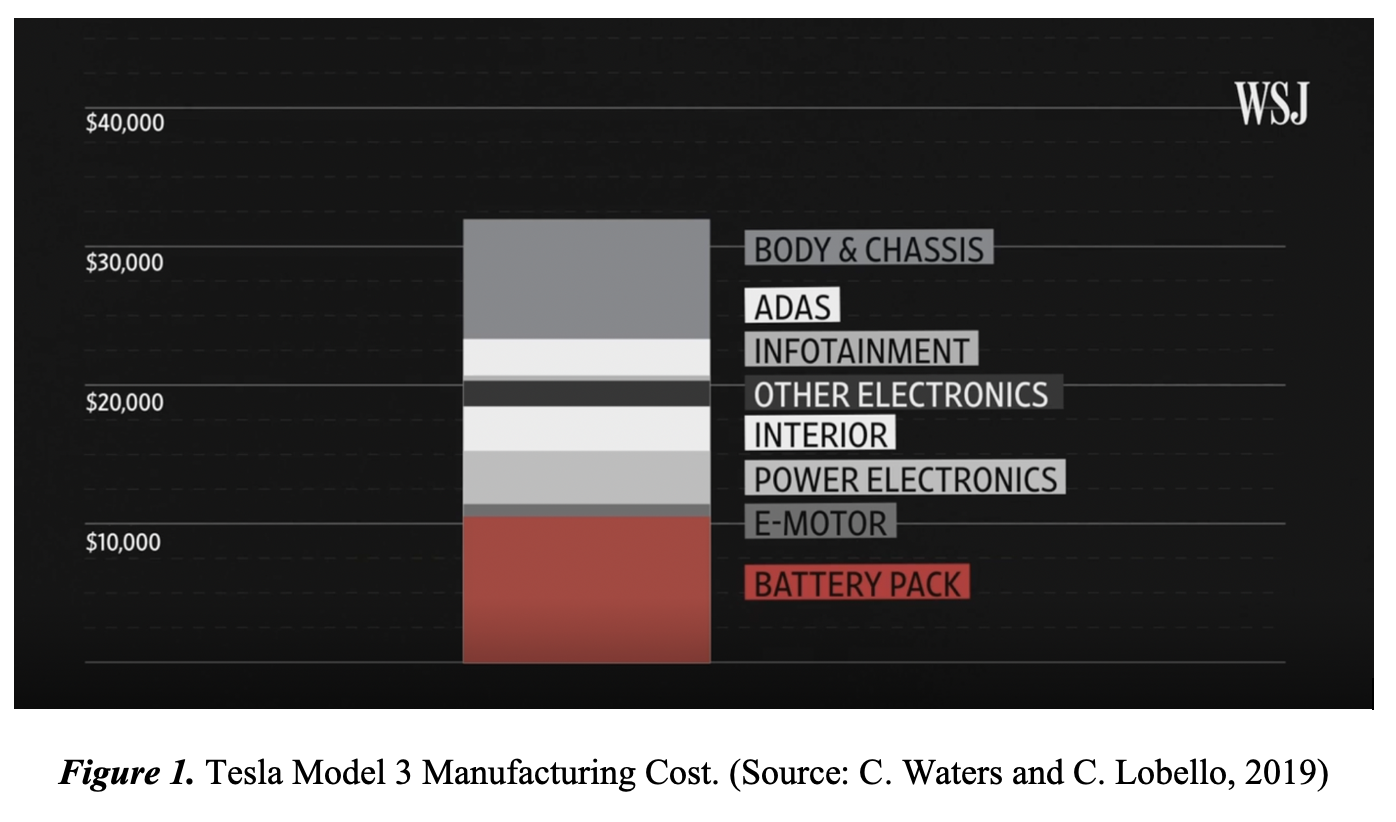

Furthermore, another issue that Tesla has faced has been working to maximize profitability on the various models offered under the Tesla brand. This is largely due to the fact that many of the raw materials that go into making lithium-ion batteries (the most efficient and high-capacity modern technology allows for), are extremely expensive to mine from the earth, transport to facilities, refine, and convert into the final batteries that are needed to operate Tesla vehicles. According to a Wall Street Journal analysis, the battery pack of any given Tesla Model 3 accounts for 40% of its total manufacturing cost as shown below (Waters and Lobello, 2019).

Figure 1. Tesla Model 3 Manufacturing Cost. (Source: C. Waters and C. Lobello, 2019)

Minimizing the costs of manufacturing is a major issue that Tesla will continue to need to work on over the next several years if the company is going to continue its goals of creating affordable, mass-market electric vehicles. Although Tesla does appear to be on track with their long-term plan of developing an affordable electric vehicle for the mass market, even their Model 3 is mostly out of reach of the working-class and middle-class consumer. With a hefty starting price of $44,490 before potential tax credits and rebates, the starting price of Tesla’s lowest-price vehicle is arguably still largely unattainable for most consumers in 2021 (Tesla, 2021). Furthermore, depending on the state the purchaser resides in, there is now the possibility that no tax credits or rebates will be received at all due to the fact that Tesla has been phased out of the original $7,500 federal tax credit after hitting their 200,000th vehicle sold in 2019 (Ulitskaya et. al, 2018). In addition to this, most states located throughout the regional Midwest offer no local incentives at all for purchasing electric vehicles compared to states located along the Pacific Coast and American Northeast (State & Federal Incentives, 2019).

Analysis I. Identification of the Firm’s Strategy

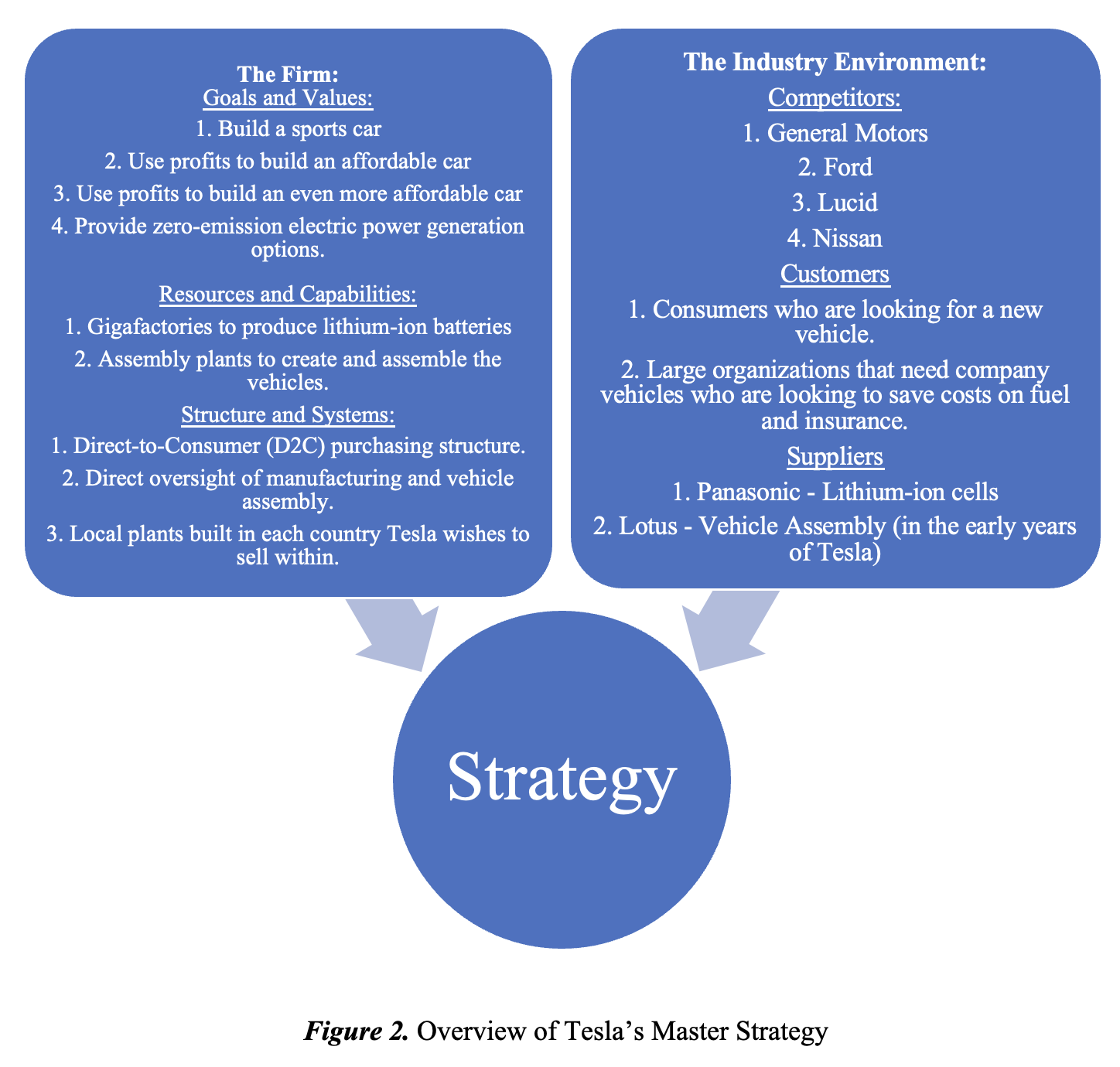

When it comes to long-term goals and strategy, there are several methods in which Tesla works to ensure that they reach long-term profitability and positive cash flows:

Figure 2. Overview of Tesla’s Master Strategy

The Firm: Goals and Values

As soon as Tesla was created by Elon Musk in California in 2003, there was already a long-term strategy in place for the organization to follow. It was a short, four-step process, but proved to be effective as the company progressed.

1. Build a sports car. Introduced in 2007, the Tesla Roadster was the company’s flagship vehicle that quickly turned the company into a national phenomenon in the United States (Grant, 2018). Created as a two-seat sports car, the original Roadster featured an electric range of 260 miles, the ability to go from 0 MPH to 60 MPH in less than four seconds, and a base price of $109,000 before customization options (Grant, 2018). After its initial rollout, the Tesla Roadster quickly became a status symbol among Hollywood celebrities and Silicon Valley entrepreneurs alike (Grant, 2018). Although it had a high price point and low overall sales numbers, attention across the U.S. quickly gained since it was a new luxury sports car based on what was a revolutionary technological platform at the time of its conception. Even more important: the reputation gained from the Tesla Roadster (as well as revenue earned from the new vehicle) is what allowed Tesla the ability to finance phase two of their internal long-term strategy.

2. Build an affordable car from those profits. With an established reputation in place and a decent revenue stream coming in from the original Roadster model, Elon Musk was now successfully able to begin phase two of the organization’s journey while minimizing his personal financial investments at this stage. With this came the introduction of the Tesla Model S. Launched in 2013, the vehicle quickly made the Tesla brand a household name after it was added to Motor Trend’s Car of the Year list and received the highest score Consumer Reports had ever awarded a vehicle in the magazine’s entire history (Grant, 2018). With the ability to seat up to five people and incorporating two trunk spaces (on both the front and back of the vehicle), the Model S was a significant diversion from the original Roadster in terms of both size and practicality. What was once a brand initially known for creating fun sports cars was now (slowly) expanding to become an all-encompassing brand of luxury electric motor vehicles. Just two years later, during this same stage Tesla also introduced the Model X, an SUV built on the same vehicular platform as the Model S. The Model X provided even more headroom and a higher ride height, more cargo space for groceries or traveling, and an equally large touchscreen infotainment system as also found in the Model S (Grant, 2018). Phase two of Tesla’s long-term growth strategy proved to be successful; although these cars were priced at a hefty premium, the vehicles began to appear throughout the continental United States instead of just major metropolitan areas like Los Angeles, San Francisco, and New York City.

3. Build an even more affordable car from those profits. Using the profits earned from the Model S and Model X, Musk began to shift his attention toward the mass market of American consumers, which is arguably where the real, major profits are made for any motor vehicle company. This led to the introduction of the Tesla Model 3 in 2017 – Tesla’s first motor vehicle aimed at the working middle class. Although the initial listing price of the Model 3 was considerably more expensive than the average new car powered by an internal combustion engine, at the time of the Model 3’s launch the United States federal government was also providing incentives to newer electric vehicle manufacturers. Early adopters of the Model 3 qualified for a federal tax credit and rebate of $7,500.00 after the purchase and use of the vehicle, and ownership of the car in larger states such as California, Texas, and New York allowed for exclusive access to HOV lanes even if there was only one occupant in the vehicle (State & Federal Incentives, 2020). With the addition of these incentives, plus annual savings from not purchasing gasoline at public stations and free over-the-air updates for the center infotainment system, early adopters of the Model 3 found the vehicle to be well worth the premium purchase price. However, this stage is when Tesla began to face serious internal manufacturing issues in regard to production output and capacity, as will be examined in Analysis V of this report.

4. In conjunction with these steps, also provide several zero-emission options for electric power generation options. At the same time that all of these new vehicles were being introduced, Elon Musk also had divisions within Tesla focusing on other areas in which the company could gain market share of the clean energy market. The two primary products introduced under this division were the Tesla Powerwall and SolarCity. The Tesla Powerwall was a product designed for households in the United States (and abroad) to allow for scaled storage of electricity for later use, be it due to a municipal power outage or lack of incoming electricity from other sources attached to the home such as solar panels and wind turbines (Grant, 2018). Tesla also created large-scale Powerwalls for business and government usage to allow for mass-scale electric grid storage usage - one of the most notable of which was purchased by Australia and officially started for electric grid use in December 2021 (Kolodny, 2021). Tesla SolarCity was another division geared toward this common objective. Primarily geared toward small-scale energy generation for single-family homes and commercial properties, SolarCity gained most of its fame when it was able to pioneer and publicly introduce the Solar Roof – a roofing tile that allowed for homeowners to replace their entire roof with the product to both protect their home from the elements and constantly generate power for use within the home itself (Grant, 2018).

The Firm: Resources and Capabilities

During the early stages of Tesla’s existence, much of the production of Tesla’s flagship Roadster model was outsourced to other companies while being sold under the Tesla brand and logo. The batteries powering the Roadster, for example, were supplied solely by Panasonic at the time of the Roadster’s creation, and manufacturing and assembly of the Roadster body and shell were handled exclusively by Lotus (Grant, 2018). At the end of the manufacturing process, one of the only things that Tesla oversaw was the design of the Roadster itself, as well as distribution to customers who bought them.

As time went on, though, and Tesla gained both revenue and market share in the United States, more and more aspects of production and assembly began to be brought directly under Tesla’s umbrella rather than being sourced out to other manufacturers. Some of the most notable instances of this were the introduction of the “Gigafactory” in Nevada and Tesla’s flagship manufacturing plant in California (Grant, 2018). Tesla wanted to make it clear to both investors and the public that the organization was in business for the long haul and that their end goal was to become a major competitor to the “Big Three” automakers, with the primary differentiator being that Tesla vehicles operated on electricity, while their American counterparts relied on gasoline and diesel fuel.

Fast forward to the present day, it is clear that Tesla has achieved this goal in several aspects. For one, production of all Tesla vehicles are now overseen by Tesla themselves and not outsourced to other companies for manufacturing or assembly. Furthermore, when it comes to specifications such as vehicle range, electric horsepower, and torque, Tesla has largely beat General Motors, Chrysler, and Ford to become the best-performing and highest-market share electric vehicles out of all American motor vehicle companies.

The Firm: Structure and Systems

Further differentiating themselves from competitors, Tesla has also introduced a radically different approach to selling their vehicles compared to other competitors within the industry. Traditionally, the method of vehicle sales and distribution within the United States has been for automobile manufacturers to mass-sell their new vehicles to car dealerships for final sale to business and personal consumers alike. However, Tesla has taken a radically different approach to this by structuring their purchasing platform to be Direct-to-Consumer (D2C). Instead of mass-producing and mass-selling their vehicles to car dealerships across the country, Tesla has customers interested in purchasing one of their products either place their order directly online with the specifications they would like to have within the item they are purchasing, or Tesla has customers come into one of their “Tesla stores” located strategically around major metropolitan areas to customize their vehicle one-on-one with a sales advisor employed by Tesla.

In addition to the Direct-to-Consumer sales model Tesla employs, Tesla also directly oversees all aspects of manufacturing of the vehicle as well as the final assembly (Grant, 2018). This has been achieved by the company by establishing “Gigafactories” across the United States and the rest of the world, or factories that are projected to be some of the largest buildings ever constructed in the entire world (Tesla Gigafactory, 2014). To help make Tesla vehicles even more accessible, the company has also been establishing these same factories across several continents to minimize the logistics of importation and exportation of their vehicles abroad.

The Industry Environment: Competitors

Although there are easily hundreds of automobile manufacturers that span across the entire planet, the focus of this report will primarily be on those also headquartered within the United States. To date, the most notable competitors to Tesla within the electric vehicle market in the U.S. are General Motors, Ford, Fisker, Lucid, and Rivian. Although Tesla was one of the first to bring the electric vehicle concept into the mainstream, many of these competitors (most notably the established “Big Three”) are quickly catching up in terms of both price and production here in the U.S. Already, several automobile manufacturers have pledged to cut production of gasoline-powered vehicles in favor of electric ones over the next several decades, and companies such as General Motors and Ford have introduced entire product lines of electric vehicles, most notably an electrified version of the Hummer by General Motors and the F-150 Lightning by Ford (Hummer: The world's first all-electric Supertrucks, 2021; Into the future with Ford, 2021).

The Industry Environment: Customers

When it comes to Tesla, the primary customers that they are attempting to engage are both wealthy and non-wealthy customers. Initially, when the company was first created the pricing of their vehicles exceeded $50,000.00-$60,000.00. More recently, however, with the introduction of the Model 3 customers in the United States have seen Tesla pricing start to lower overall across all their models. Based on all the analysis so far, it would seem that Tesla’s overall goal is to maximize their market share of the electric vehicle market by lowering their prices in conjunction with each new increase of production capacity at their manufacturing facilities.

The Industry Environment: Suppliers

At the beginning of Tesla’s journey as an electric vehicle manufacturer, most of the production and assembly of the Tesla Roadsters were completed by other organizations. The battery cells, for example, were manufactured and finalized by Panasonic before being assembled into the rest of the vehicle by Lotus (Grant, 2018).

Fast forward to today, however, and this is no longer true. From the first step to the last, almost every aspect of the manufacturing and assembly processes of Tesla vehicles are being overseen by Tesla themselves within their regular factories and their Gigafactories. One exception remains, however: the battery packs being installed into Tesla vehicles. This part of the manufacturing process is still being outsourced to Panasonic as this has become one of their main sources of revenue due to the changing global economy.

Analysis II. The Firm’s Performance Data

From the public eye, Tesla appears to be a very successful company that is growing at an unprecedented magnitude compared to others within the industry. However, upon reviewing the company’s financial reports, it does appear that Tesla is facing some internal issues across various aspects of their company.

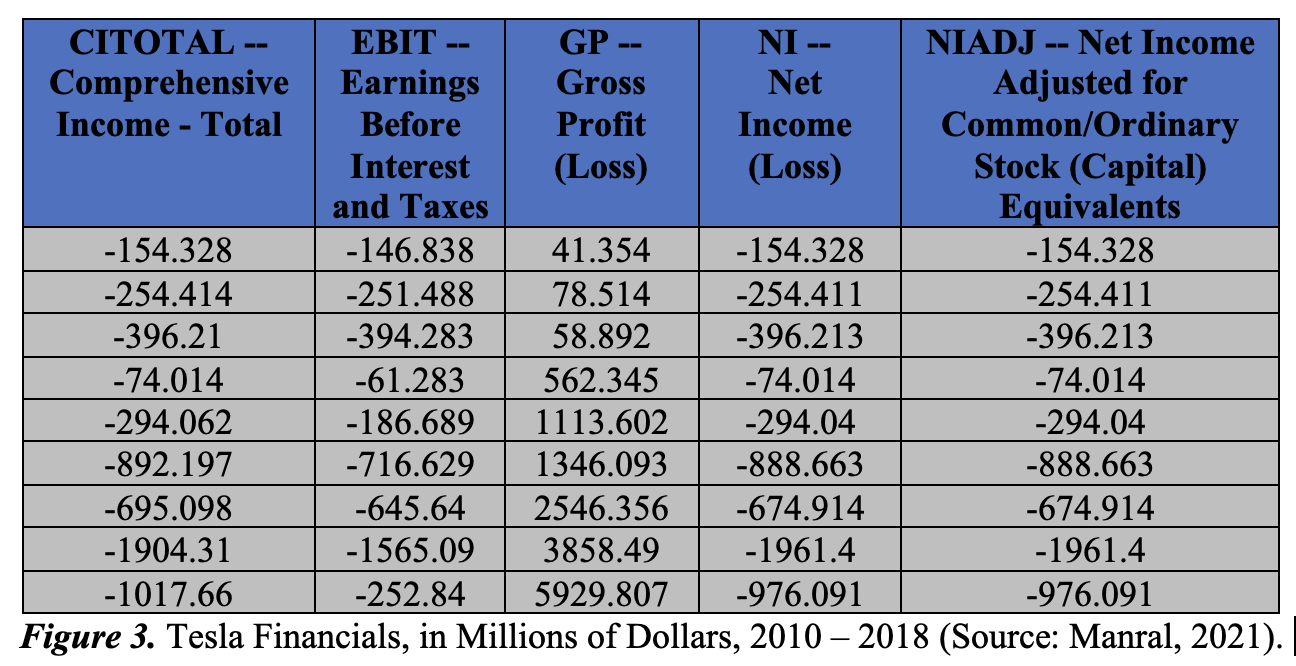

Figure 3. Tesla Financials, in Millions of Dollars, 2010 – 2018 (Source: Manral, 2021).

For starters, as shown in the table above, all of Tesla’s operating and net incomes are negative for the years of 2010 to 2018. From the outside looking in, this would show overall that Tesla is struggling to maintain short-term profitability across all of their divisions (Tesla Automotive, Tesla Powerwall, and SolarCity) here in the United States. However, there are other factors regarding Tesla that need to be considered before a conclusion can be made:

1. The high barrier to entry in the automotive industry.

a. Tesla operates in an industry that holds an extremely high barrier to entry in the United States. Manufacturing, assembling, and (finally) selling automobiles in the U.S. is a tremendous feat all on its own that requires billions of dollars of infrastructure and thousands of man-hours to complete. When Tesla was created, it also garnered considerable media attention just due to the fact that it was one of the first automotive companies to be created in the United States in over fifty years.

2. The other factors required for continuous, sustainable operation.

a. As mentioned in point number one, the high barrier to entry in the automotive industry is largely due to the fact that it requires a tremendous amount of infrastructure to be established before the company can begin to (1) manufacture the vehicles in question and (2) produce them at a scale that minimizes cost and maximizes overall profitability. This includes the manufacturing facilities that must be built in the first place to start building the vehicles in question, the parts, tools, and other pieces that must be installed in the manufacturing facilities to facilitate the building of their new vehicles, the logistics of marketing these vehicles and convincing consumers that they are as reliable as the vehicles coming from their established competitors, and transporting them to the customers once they actually do sell.

b. Furthermore, various additional factors such as access to a skilled labor force, an electric grid powerful enough to facilitate the needed energy input to create the vehicles in question, and government support to pursue such an endeavor are also needed before a company such as Tesla can continue to pursue their organizational goals and long-term strategy.

With these factors in mind, as well as the trends shown in Figure Three, it does appear that (overall) Tesla is moving in the right direction operationally and financially. Tesla’s gross profits have progressively grown year-after-year during the period of 2010 to 2018. This shows that both sales and overall consumer interest are growing in the Tesla brand, and that the company should continue to grow over the next decade as long as economic conditions hold steady.

Analysis IV. The Firm’s External Environment

Horizontal: Competition from Substitutes

When Tesla was first starting out in the late 2000’s and early 2010’s, there was not a lot of threats of substitutes in the United States. Electric vehicles were largely unused by Americans and not being researched by larger automotive companies prior to Tesla’s creation, and dependence on internal combustion engine vehicles was at an all-time high among the automotive marketplace.

At the time, the only primary substitutes that a consumer could choose from in this regard were the Toyota Prius and Chevrolet Volt, but it must be noted that both of these substitutes are hybrid-electric vehicles (HEVs) and not fully-electric motor vehicles (EVs) like Tesla. As a result of this, if a consumer were to choose one of the substitutes, they would still be reliant on gas stations instead of being able to fully charge their vehicle at their home or a full-service electric charging station.

In regard to profitability, it is hard to argue that these substitutes would outright take from Tesla’s own profit over the long run. As the market continues to diversify and introduce new lines of vehicles that run on different forms of energies and fuels, consumers will lean one way or another in terms of preferences. For example, a consumer that determines an electric car would be best for them would probably not choose a hybrid electric vehicle instead since that would still mean they would have to visit the gas station regularly.

Horizontal: Competition from Entrants

After Tesla rose to fame on a global scale, several other competitors were founded in Tesla’s home state of California, as well. Two of the other well-known entrant competitors our society knows today are Fisker and Rivian, both of which also specialize in manufacturing fully electric vehicles.

For the moment, it does not appear as though Tesla needs to worry about significant losses in profits from these new entrants in the industry. Generally speaking, Fisker and Rivian have significantly less infrastructure established and facilities in operation compared to Tesla. This directly translates into vehicle output here in the United States – the less infrastructure and facilities there are for these two entrants to make their vehicles, the less market share the companies will take up overall compared to Tesla. However, this is something that Tesla should keep an eye on later down the road – especially within the next few decades. The desire for electric vehicles is growing steadily within the United States, and new entrants such as these may gain traction as pricing for electric vehicles market-wide begin to decrease to a level that most working class and middle-class consumers can begin to afford them.

Horizontal: Competition from Established Rivals

In addition to the new entrants of Fisker and Rivian, established rivals such as Ford and General Motors also began researching their own fully electric vehicles after seeing how Tesla surged in popularity across the United States. In 2020, General Motors announced intentions to re-release their once-discontinued Hummer as a fully electric vehicle in both pickup truck and SUV forms (Hummer, 2020). The same year, Ford announced a fully electric version of the Mustang known as the Mustang Mach-E and reintroduced the Ford F-150 Lightning model as a fully-electric pickup truck with an estimated 300 miles of range (Into the Future with Ford, 2021).

This is the area in which Tesla should worry the most when it comes to loss of potential market share and overall profits. General Motors and Ford both have lengthy, significant reputations behind them as automobile manufacturers, and both already have most of the necessary infrastructure in place at their existing manufacturing and assembly plants across the United States and abroad. In addition to this, both of these companies listed as examples already have well-established supply chains, manpower, and vendors to purchase external parts from that they do not make on their own, further easing the process of creating new vehicles to sell to consumers. It is quite arguable that over the next few decades, as these existing automotive manufacturers ramp up production on electric vehicles it could significantly chip at Tesla’s overall profits and market share within the electric vehicle industry.

Vertical: The Power of Suppliers

When it comes to supplier power, Tesla does exercise considerable wield in this aspect. Although Tesla may take up a small percentage of the overall market share of all vehicle sales within the United States, they are a major player in the electric vehicle division of the automotive industry. If, for example, Panasonic were to raise their prices on Tesla on the battery packs that they produce for their vehicles, Tesla could easily walk away from the established contracts they have made with Panasonic and look for other manufacturers who are operating within the electric vehicle battery pack industry.

Vertical: The Power of Buyers

From the buyer’s perspective, there is significant power that remains at the hands of American consumers. For one, because the United States does operate within a free-market system, most Americans are going to choose the route that saves them the most money in the short run. In many instances, this largely means either choosing an internal combustion engine vehicle or an electric vehicle that is priced within the same price range.

As a result of this, Tesla must work hard to ensure they are reducing their costs to the consumer as much as possible, especially in regard to the Model 3. If Tesla cannot continue to minimize their costs so their savings can be passed on to the consumer, then Tesla will not be able to achieve their long-term goal of being a mass-market automobile manufacturer and instead remain a niche luxury auto maker within the electric vehicle realm.

Analysis V. The Firm’s Internal Environment

In regard to the internal environment of Tesla, Inc., it is quite clear that the biggest aspect of the company’s competitive advantages lies within their internal infrastructure, manufacturing operations, and marketing.

During the early 2010s, Tesla began making billions of dollars’ worth of expenditures in regard to their corporate infrastructure. This included building both their primary manufacturing facilities as well as their “Gigafactories” to assist with the production process of Tesla vehicles from start to finish. Furthermore, they also began establishing their own electric vehicle charging network known as the Tesla Superchargers to help entice customers to purchase their products, as “range anxiety” became a mainstream worry among American consumers.

Furthermore, the manufacturing operations that Tesla has established within these factories and Gigafactories are a feat all within its own. Starting up manufacturing facilities, especially in an economy that favors office and service jobs over production jobs can be extremely difficult in the United States. The fact that Tesla has been able to achieve all of this in less than a decade has shown that the company is committed to long-term growth over short-term profit.

In addition to this, Tesla has done extremely well in terms of marketing their vehicles to the general public. Not only have they managed to make their branding and vehicle designs look futuristic by incorporating items such as twelve-inch touchscreens and fully autonomous driving into their cars, but they have also established a “coolness” factor that is extremely hard to generate in today’s era of marketing and corporate-societal relations. Very few organizations have been able to achieve this in the United States – Tesla has marketed themselves to join the ranks of companies like Apple and Whole Foods rather than companies like Ford and General Motors. The value that this creates is a league all of its own – if or when a customer is in the market for an electric vehicle, with what Tesla’s marketing team has created in the United States, their company will be one of the first that customers look to when shopping for an electric vehicle.

Strategic Alternative I

There are several things that Tesla must take into consideration over the next few decades:

1. Electric vehicles will take up significant market share of internal combustion engine vehicles.

a. Based on the trends our society has been seeing over the past decade, electric vehicle usage has been steadily rising in relation to combustion engine vehicles.

2. As electric vehicle manufacturing becomes more mainstream, Tesla’s overall cost to manufacture will drop.

a. This is largely in part due to the fact that other suppliers and manufacturers will see their operating costs drop, as well, as their manufacturing processes become more streamlined for the products in question.

3. Bargaining power of buyers will change as electric vehicles become more mainstream and internal combustion engine cars are phased out.

a. As there are less options in terms of gasoline vs. diesel vs. electric cars, buyers will overall have less bargaining power when it comes to fluctuations in pricing. If, for example, ten years from now Tesla were to raise their prices on the Model 3, sales would not drop as much as they would now since consumers would have less overall vehicles to choose from for their everyday car.

Strategic Recommendation

Based on the information provided in this report, it is the primary recommendation that Tesla continue to pursue their objectives of achieving productions of scale as well as continuing their efforts to minimize manufacturing costs of the more affordable Tesla Models. It must be factored into the conversation that the electric vehicle industry in the United States is still a relatively new one compared to the internal combustion engine automotive industry, and many of the cost issues that Tesla is facing today is largely in part to the fact that other industries operating partially or wholly in the electric vehicle industry are still starting up, as well.

Panasonic, for example, is a large distributor of battery packs for electric vehicles, but this is not the primary industry the company has been operating in for its entire existence. This is a relatively new venture for Panasonic, too, and over time as they streamline their manufacturing processes of the battery packs they sell to Tesla, their costs (and therefore prices) will go down, as well. The same concept applies to Tesla’s competitors, Rivian and Lucid, as well as all of the existing internal combustion engine automotive manufacturers that are working to transition their product lines to electric vehicles instead.

Furthermore, Tesla is well on its way to achieving profitability further on down the line of their corporate existence. As examined in Analyses II and III of this report, gross profits are growing for the company overall with each continued year of existence. Additionally, costs of manufacturing Tesla Model 3’s on a per-vehicle basis are also going down as Tesla streamlines their manufacturing processes across all of their facilities. For now, the largest factor that seems to be playing into Tesla’s current pricing issues is time, more than anything else.

Conclusion

Tesla is an organization that has a lot to go through before it can reach long-term profitability here in the United States and abroad. However, with the concepts and analyses presented in this report, it is clear that founder and CEO Elon Musk and Tesla as an organization are hard at work to achieve this goal. With continued revenue coming in from new vehicle sales from the Tesla Model S, X, 3, and the Cybertruck on the way in 2022, it will only be a matter of time before aspects such as their annual gross profit and net income move from the negative value range into the positive range on their annual 10-K filed with the United States Securities and Exchange Commission. Despite all of the negative data included in this report, it will be interesting to see how Tesla continues to perform in the future as the company ramps up production of more mass-market vehicles like the Model 3 (and rumored Model 2) and rolls out already-announced vehicles such as the Cybertruck and Tesla Semi within the next few years.

While the overall performance data for now appears to be negative for Tesla, the facts that (1) Tesla is a relatively new company among a large pool of established competitors and (2) a significant amount of time, money, and effort must be put into developing infrastructure for the company to continue to operate for the long-term future must remain at the forefront of all internal and external investors’ minds as Tesla continues to work on expanding market share within the automotive industry.

References

Committing to an all-electric future: General Motors. Committing to an All-Electric Future | General Motors. (n.d.). Retrieved December 8, 2021, from https://www.gm.com/commitments/electrification.

Fisker Inc.. Home of The Fisker Ocean, and Sustainable Electric Vehicles. (n.d.). Retrieved December 8, 2021, from https://www.fiskerinc.com/.

Grant, R. M. (2018). Contemporary Strategy Analysis, Enhanced eText (10th Edition). Wiley

Global Education US. https://reader.yuzu.com/books/9781119495673.

Hummer: The world's first all-electric Supertrucks. Introducing the GMC HUMMER EVs | Electric Truck & SUV. (n.d.). Retrieved December 8, 2021, from https://www.gmc.com/electric/hummer-ev.

Into the future with Ford. Ford® All-Electric Vehicles | Say Goodbye to Gas. (n.d.). Retrieved December 14, 2021, from https://www.ford.com/powertrains/battery-electric-vehicles/?intcmp=hp-explore-cta-bev.

Kolodny, L. (2021, December 8). Australia switches on Victoria Big Battery powered by Tesla Megapacks. CNBC. Retrieved December 9, 2021, from https://www.cnbc.com/2021/12/08/australia-switches-on-victoria-big-battery-powered-by-tesla-megapacks.html.

Lucid Motors. Luxury Electric Cars. (n.d.). Retrieved December 8, 2021, from https://www.lucidmotors.com/.

Manral, Dr. L. (2021). MGMT 4813: Strategic Management. Edmond, OK; The University of Central Oklahoma College of Business, Commenced Fall 2021.

Model 3: Tesla. Tesla. (2021). Retrieved December 1, 2021, from https://www.tesla.com/model3/design#overview.

Panasonic. (n.d.). What we do | Panasonic North America - United States. Panasonic North America. Retrieved December 8, 2021, from https://na.panasonic.com/us/what-we-do.

Rivian: Electric adventure vehicles. Rivian. (n.d.). Retrieved December 8, 2021, from https://rivian.com/.

Shepardson, D. (2021, November 3). U.S. Democrats' plan boosts EV tax credit eligibility to pricier trucks, suvs. Reuters. Retrieved December 1, 2021, from https://www.reuters.com/business/autos-transportation/us-democrats-plan-boosts-ev-tax-credit-eligibility-pricier-trucks-suvs-2021-11-03/.

State & Federal incentives. Plug-In America. (2020, June 9). Retrieved December 1, 2021, from https://pluginamerica.org/why-go-plug-in/state-federal-incentives/?location=co.

Tesla, Inc. (2020, December 31). Form 10-K: Tesla, Inc. United States Securities and Exchange Commission. Retrieved December 10, 2021, from https://www.sec.gov/Archives/edgar/data/1318605/000156459021004599/tsla-10k_20201231.htm. Report Approved by Chief Accounting Officer Vaibhav Taneja.

Tesla Gigafactory. Tesla. (2014). Retrieved December 8, 2021, from https://www.tesla.com/gigafactory.

Ulitskaya, J., Newman, J., Geiger, J., Bruzek, J., Normile, B., & Bragman, A. (2018, August 2). Shopping for a tesla? what you need to know about tax credits: News. Cars.com. Retrieved December 13, 2021, from https://www.cars.com/articles/tesla-tax-credit-is-expiring-heres-everything-shoppers-need-to-know-1420700959540/.

Waters, C., & Lobello, C. (2019, February 19). The secret to why a Tesla costs so much (hint: Batteries). The Wall Street Journal. Retrieved December 1, 2021, from https://www.wsj.com/video/the-secret-to-why-a-tesla-costs-so-much-hint-batteries/65F3A21D-0837-4DA6-B739-612124815603.html.